Register Here For eMail Copy Of Executive Summary

WHAT SETS US APART

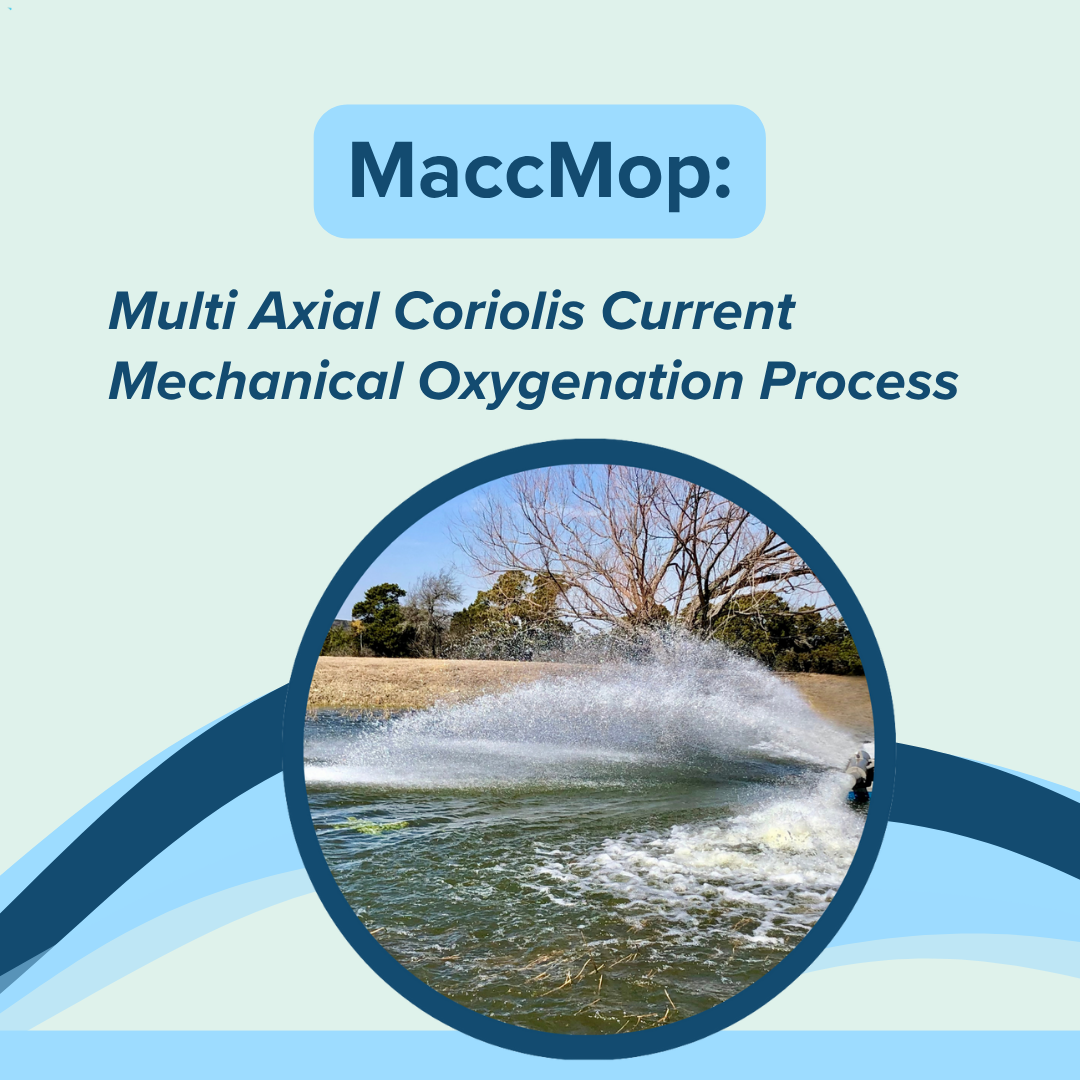

We specialize in providing chemical-free industrial water treatment solutions through our proprietary Multi Axial Coriolis Current Mechanical Oxygenation Process (MaccMop), a proven technology that efficiently treats wastewater while minimizing environmental impact.

This innovative process has been rigorously tested and refined over 18+ years, enabling the Company to deliver cost-effective and sustainable solutions to Municipal, State and Federal

water bodies, wastewater plants, and industrial water treatment plants such as refineries, processing plants and paper mills. Together with the Corps of Engineers, the technology played an integral role in hurricane disaster relief.

With a focus on reducing the environmental footprint of wastewater treatment, the Company’s technology is validated by leading regulatory bodies, such as the USDA and EPA, ensuring its reliability and compliance with industry standards.

"Our technology speeds up the natural oxidation process from years and months, to minutes, hours and days!

The MaccMoppers 25/50 are self-contained, energy efficient, chemical-free, mini water treatment plants capable of replacing 4–8 traditional aeration & 4-6 mixing units—offering exponential cost savings and unprecedented performance."

Christopher Randolph, CEO

Industry Verticals Using MaccMoppers

-

Waste Management

pH restoration, drastic reduction of TDS, TSS, BOD, COD, Turbidity, and Fecal to BELOW acceptable EPA limits using our MaccMoppers technology. We eliminate the Methanogen bacteria that create methane and also removes ammonia produced as a by-product of the microbial decomposition of the organic nitrogen compounds in fecal matter. hus, eliminating the associated odors from methane and ammonia.

-

Feedlots, Cattle & Dairy Farms

MaccMoppers eliminates the Methanogen bacteria that create methane. It also removes ammonia produced as a by-product of the microbial decomposition of the organic nitrogen compounds in manure. Thus, eliminating the associated odors from methane and ammonia.

-

Mills - Steel, Pulp & Paper, Plywood, Textile & Aluminum

Corrects water imbalances in reclamation ponds present that use chemicals and degreasers to wash down and sterilize processing equipment and/or chemical production byproduct runoff

-

Produced Water

Frack drilling creates Produced Water (PW) which consists of high salinity, dissolved and suspended solids like salts, dissolved organic compounds (including hydrocarbons), heavy metals, and chemicals used during drilling operations. Our MaccMoppers technology restores pH to Normal, Reduces TDS, TSS, and BOD which allows the reuse of the (PW) water

-

Municipal Wastewater

pH restoration, drastic reduction of TDS, TSS, BOD, COD, Turbidity, and Fecal to BELOW acceptable EPA limits using our MaccMoppers technology. We eliminate the Methanogen bacteria that create methane and also removes ammonia produced as a by-product of the microbial decomposition of the organic nitrogen compounds in fecal matter. hus, eliminating the associated odors from methane and ammonia.

-

Processing Plants - Produce, Meat, Fish & Rendering

Corrects water inbalances in reclamation ponds present that use chemicals and degreasers to wash down and sterilize processing equipment and/or chemical production byproduct runoff

-

Aquaculture

MaccMoppers results are relevant to all freshwater fish/seafood farming

-

Wineries

PG&E (California) offers an annual rebate program for electricity savings using our MaccMoppers technology

-

Ponds, Lakes & Lagoons

OurMaccMoppers technology eradicates algae by limiting nutrients, disrupting algae spores, and speeding up decomposition

-

Chemical Plants

Corrects water imbalances in reclamation ponds present that use chemicals and degreasers to wash down and sterilize processing equipment and/or chemical production byproduct runoff

-

Electrical Plants

Our MaccMoppers technology is used for cooling and odor control

-

Mining

Corrects water imbalances in reclamation ponds present that use chemicals and degreasers to wash down and sterilize processing equipment and/or chemical production byproduct runoff

Weather & Climate Disasters

Disaster recovery in conjunction with FEMA, EPA, DEQ, Corps of Engineers, and other Agencies.

Deployed by Corp of Engineers during Katrina and Rita Hurricanes

Private Initial Round Offering

We are excited to offer a limited Private Friends and Family Investment Round in our pioneering water technology company, focused on sustainable, scalable solutions for water purification and reclamation. This is an exclusive early-stage opportunity to support a mission-driven venture addressing critical global water challenges through innovative, patented technology.

Funds raised will accelerate product development, expand pilot programs, and position the company for broader commercial rollout and institutional funding. Investors in this round will benefit from favorable terms and the chance to be early stakeholders in a company poised for impact and growth in the rapidly expanding clean water market.

Now is the time to invest in innovation that matters. Complete the registration form and we will email you the Pro Forma.

RefurbRangers.com

OUR PRIVATE / NON-PROFIT 501(c)3 PARTNERSHIP:

Refurb Rangers is a socially conscious company dedicated to supporting veteran causes and empowering veterans to succeed. We specialize in refurbishing and redeployment of abandoned industrial equipment, offering high-quality refurbished products to our customers while creating meaningful opportunities for veterans.